Overview#

This section provides a brief explanation of what SunPeek is and how it works!

What is SunPeek?#

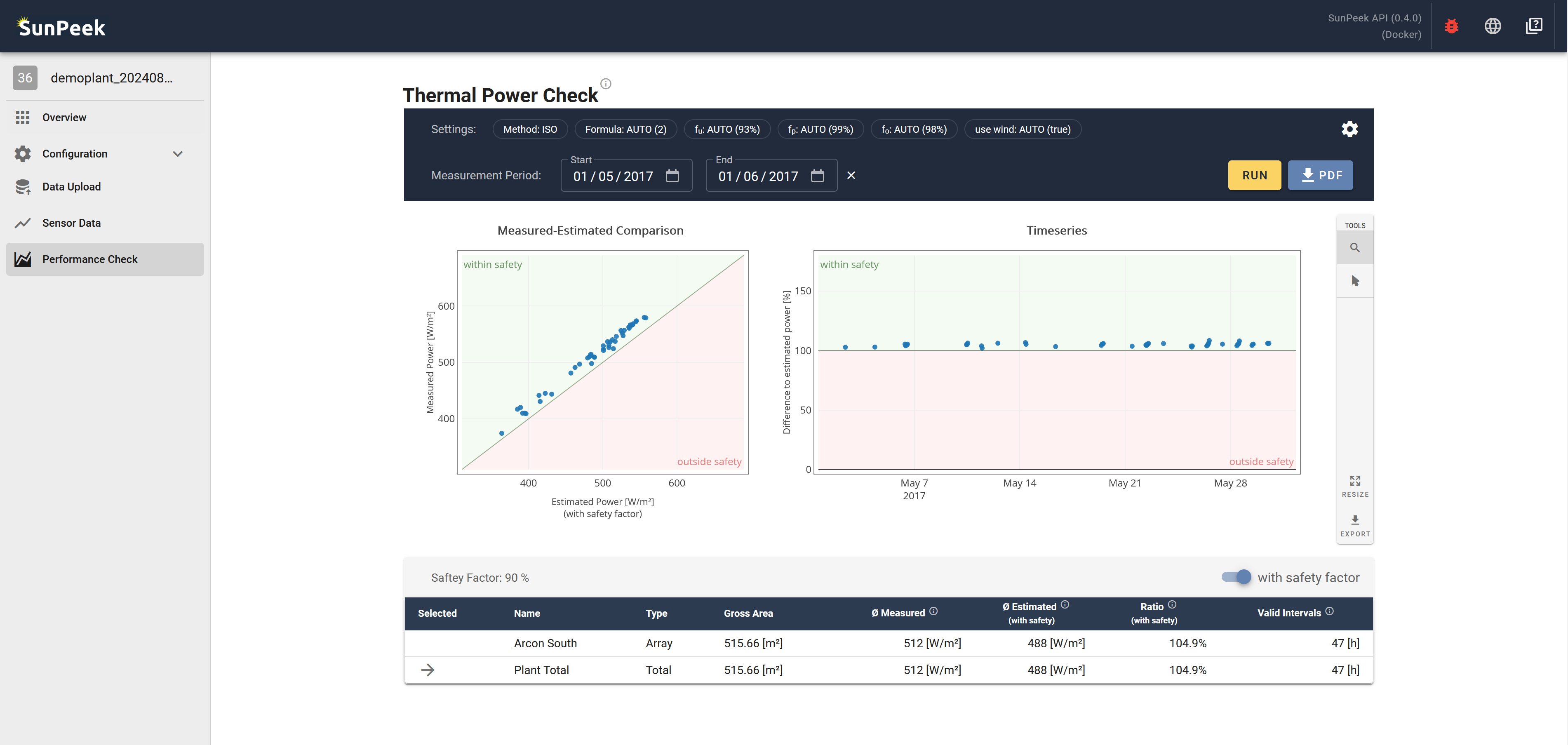

SunPeek is a open-source software tool for the performance assessment of solar thermal plants, based on the Power Check of ISO 24194:2022. The software is based on Python, but user can also interact with SunPeek via the user friendly Web-Interface which is accessible via the browser (see screenshot above).

SunPeek is implemented as a community-tool, aiming to make quality-assurance of solar-thermal plants accessible to everyone. Hence, you can use the software free of charge - also for commercial use. The goal is to achieve a trusted, harmonized, consistent, high-quality, and well-maintained implementation of ISO 24194 for the solar community.

What can it be used for?#

SunPeek can be applied to solar-thermal plants in operation if measurement data is available. More specifically, the following use-cases are possible using the ISO Power Check method:

Does my collector work as expected?

SunPeek allows to estimate the power of solar-thermal collectors at certain valid intervals. The estimated power can then be compared with measured power, to assess if the collector works as expected. For example, this might be used for quality assurance or even collector-guarantees.

How does collector performance change over time?

A similar procedure can be used to monitor the collector performance. Again, SunPeek computes the estimated power output of the collectors in certain valid intervals. By checking the ratio of measured versus estimated power over time, one can identify performance degradation or performance increases. For example, this can be used to check the effect of a collector cleaning on the collector performance (see graph below)

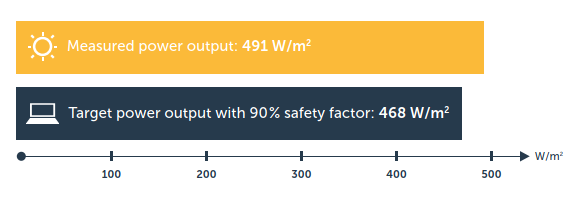

Example - Assessment

This shows an example result of a collector assessment. The ISO 24194 power check is fulfilled if the measured power output during valid operating intervals is greater then the target power ouput including a safety margin. A check requires at least 20 hours with valid operating contidions (We will cover what is considered valid in the next section).

In the depicted case, the power check according to the ISO 24194 is fulfilled.

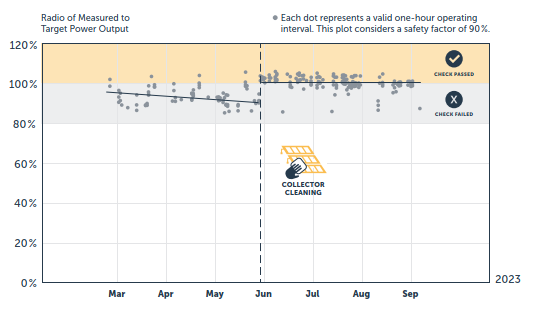

Example - Monitoring

This shows an example of a collector cleaning at a plant with severe dust pollution. The plot depicts the ratio of measured versus estimated power for all valid intervals. (We will cover what is considered valid in the next section). Note that the dots are originally close to 100% but then decrease - indicating a collector degradation. After a cleaning event, the collector performance is close to 100% again.

How does it work?#

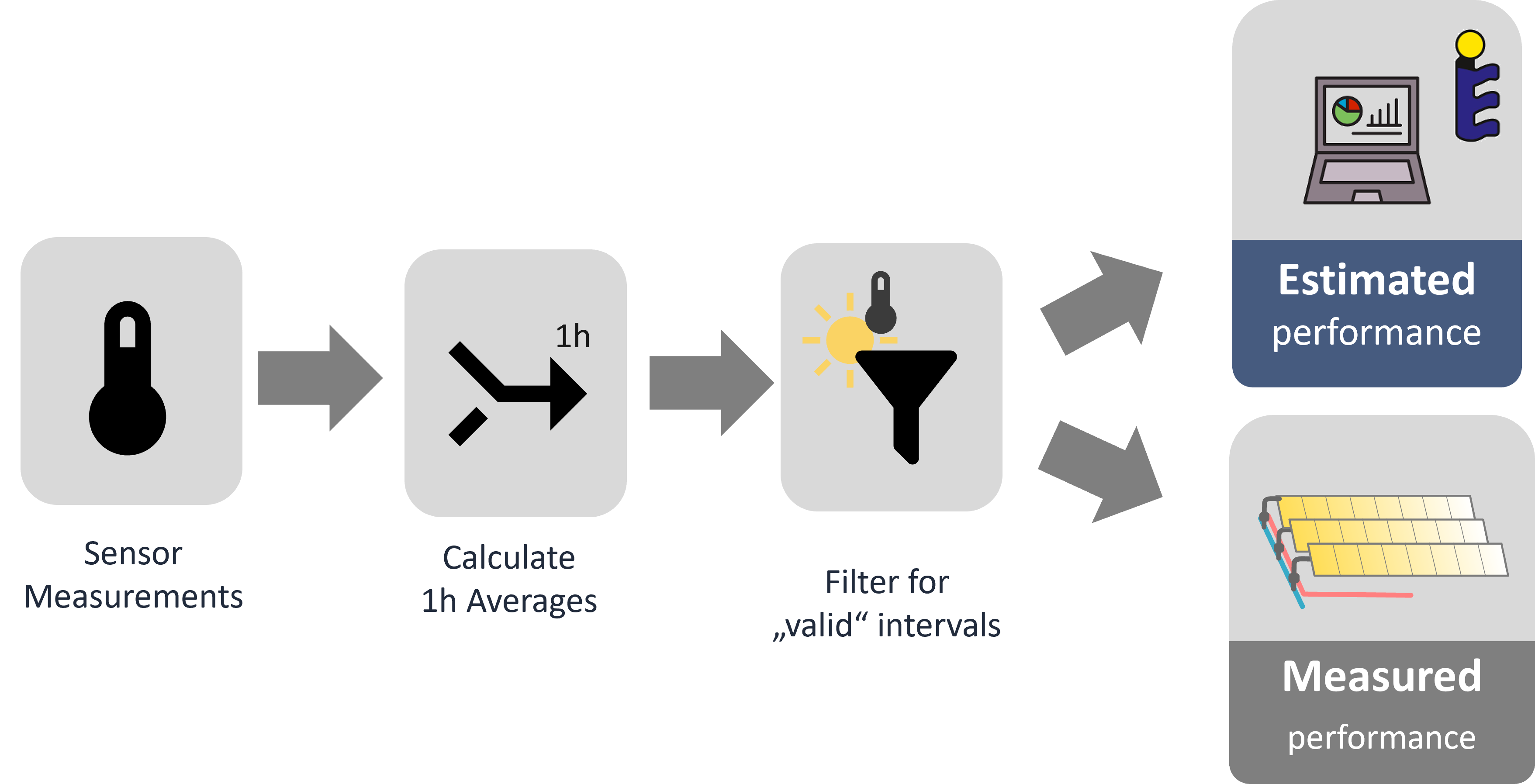

Both use cases above are based on the ISO 24194:2022, which describes how the Power Check comparison should be done. In principle, the following steps are carried out:

Measurements: As a prerequisite, the ISO method requires some sensor measurements. On one hand, it needs a heat meter (or alternatively flow meter and temperature of flow and return) to calculate the measured power. And on the other hand, it requires irradiation, ambient temperature, and the collector temperature to compute the estimated power based on the solar-keymark equation (ISO 9806).

Averaging: The measurement values are then averaged in 1h intervals.

Filtering: Next, the data is filtered so it only contains valid 1h intervals. These filter include a minimum irradiation (e.g., > 600 W/m²), stable operating conditions based on the collector temperatur change (e.g. <= 5K), low wind velocity (< 10m/s), high enough ambient temperture (>5°C), and no collector-shading. These restrictions ensure a stable comparison between measurement and estimations.

Comparison: Finally, estimated power is calculated using the solar-keymark equation (ISO 9806). The estimated power is then compared with the measured power within “valid” intervals. To account for uncertainties a safety factor (0-100%) is applied.

Note

However, this is only a very high-level overview. You can find detailed information about the procedure in the ISO 24194:2022 and in the Guide to ISO 24194 (under development).

What is your benefit?#

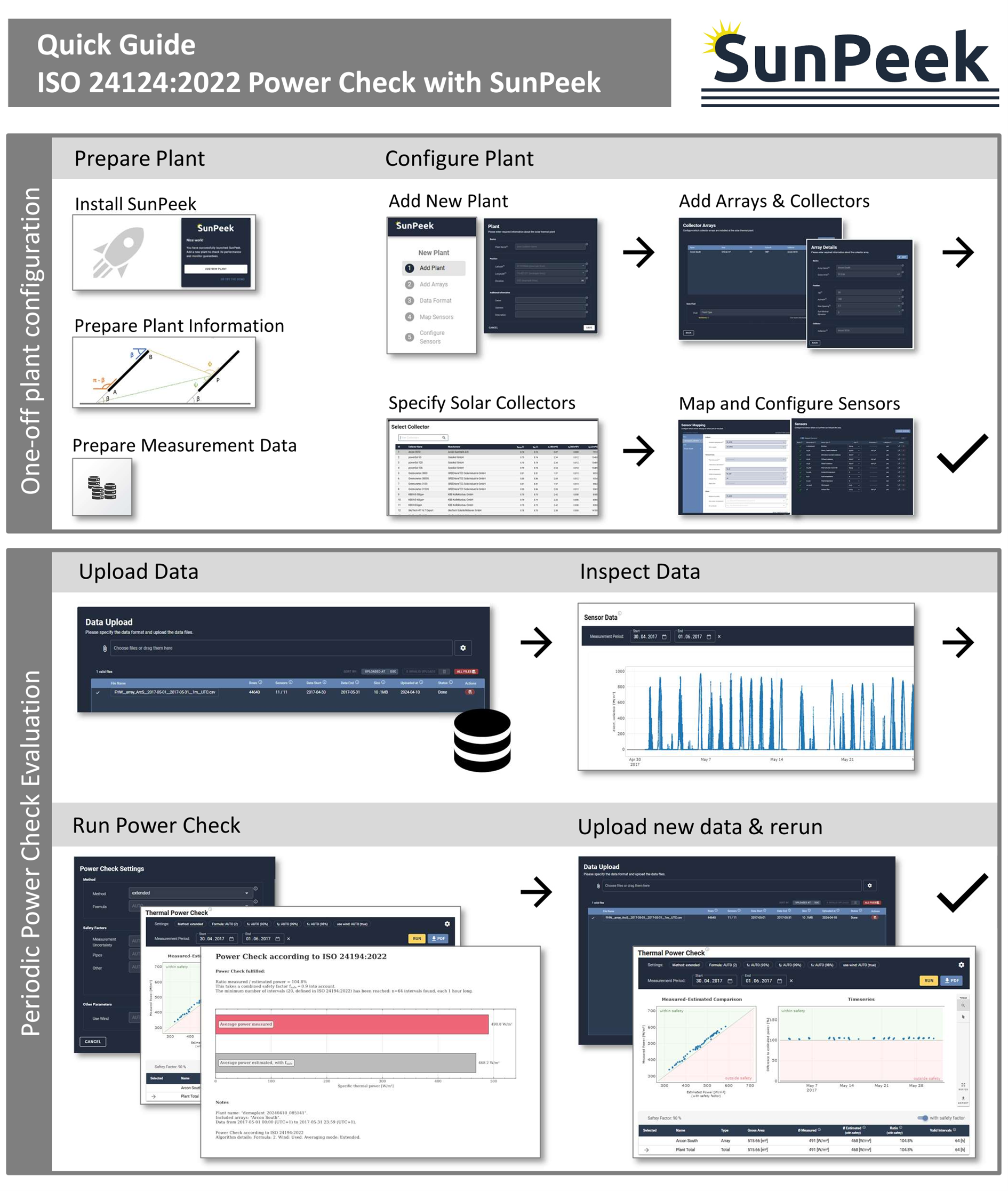

With SunPeek, you don’t have to implement the ISO 24914:2022 yourself. Instead, SunPeek takes care of the complicated parts and guides you through the procedure with it’s user interface. All that is left to the user is configuring your plant and collectors, and upload measurement data.

Aiming to make quality-assurance more transparent and accessible for everyone, we tried our best to make this process as easy and fun as possible. The following figure provides an overview on how the Power Check can be applied using SunPeek.

Next Steps#

Installation - explaining how SunPeek can be installed.

Tutorial - explaining how to use SunPeek using a demo dataset.